Testing Facilities

Our commitment to quality is driven by a culture of continuous improvement and a strong customer-centric approach.

TESTING FACILITIES

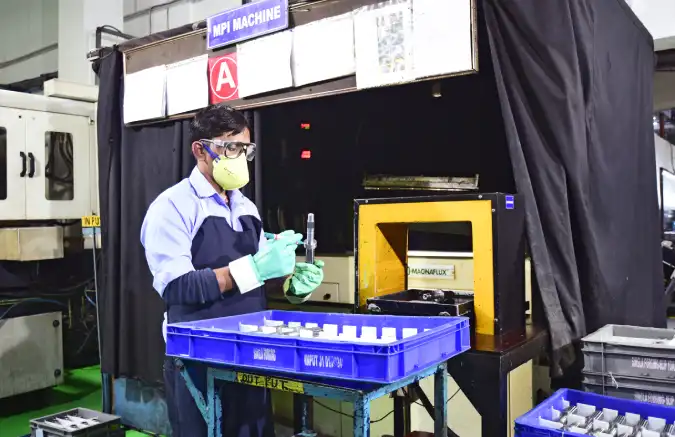

Our in-house testing facilities are equipped with cutting-edge technology to ensure the highest level of precision and quality in every component we manufacture.

These advanced tools and machines enable us to thoroughly inspect and validate the mechanical, dimensional, and surface properties of our products, ensuring they meet stringent automotive industry standards.

Our testing capabilities include the following high-tech equipment:

- Coordinate Measuring Machine (CMM)

- Contour Testing Machine (CTM)

- Emission Spectrometer

- Inverted Metallurgical Microscopes

- Universal Tensile Testing Machine (UTM)

- Roughness Testers

- Coating Thickness Testers

- Profile Projectors

- Air Gauges

- Spline Qualification Gauges

- Hardness Testing Machines including Touch Screen Computerized Brinell Hardness Number (BHN), Hardness Rockwell B Scale (HRB), Hardness Rockwell C Scale (HRC), and Vickers Hardness (HV).

- Roughness Testers