Quality

At SFL, quality assurance is a core aspect of our manufacturing process, ensuring that every component meets the highest standards of precision and reliability.

As an IATF 16949:2016 certified company, we adhere to strict automotive industry standards, focusing on continuous improvement, defect prevention, and process optimization.

Our advanced testing and inspection equipment allows us to conduct thorough inspections at every stage of production, ensuring dimensional accuracy, material integrity, and optimal performance.

STANDARD ROOM

Our Standard Room is an integral part of our quality assurance and production process.

This specialized facility is designed to maintain strict environmental conditions and standards, ensuring the accuracy, consistency, and reliability of our forged components.

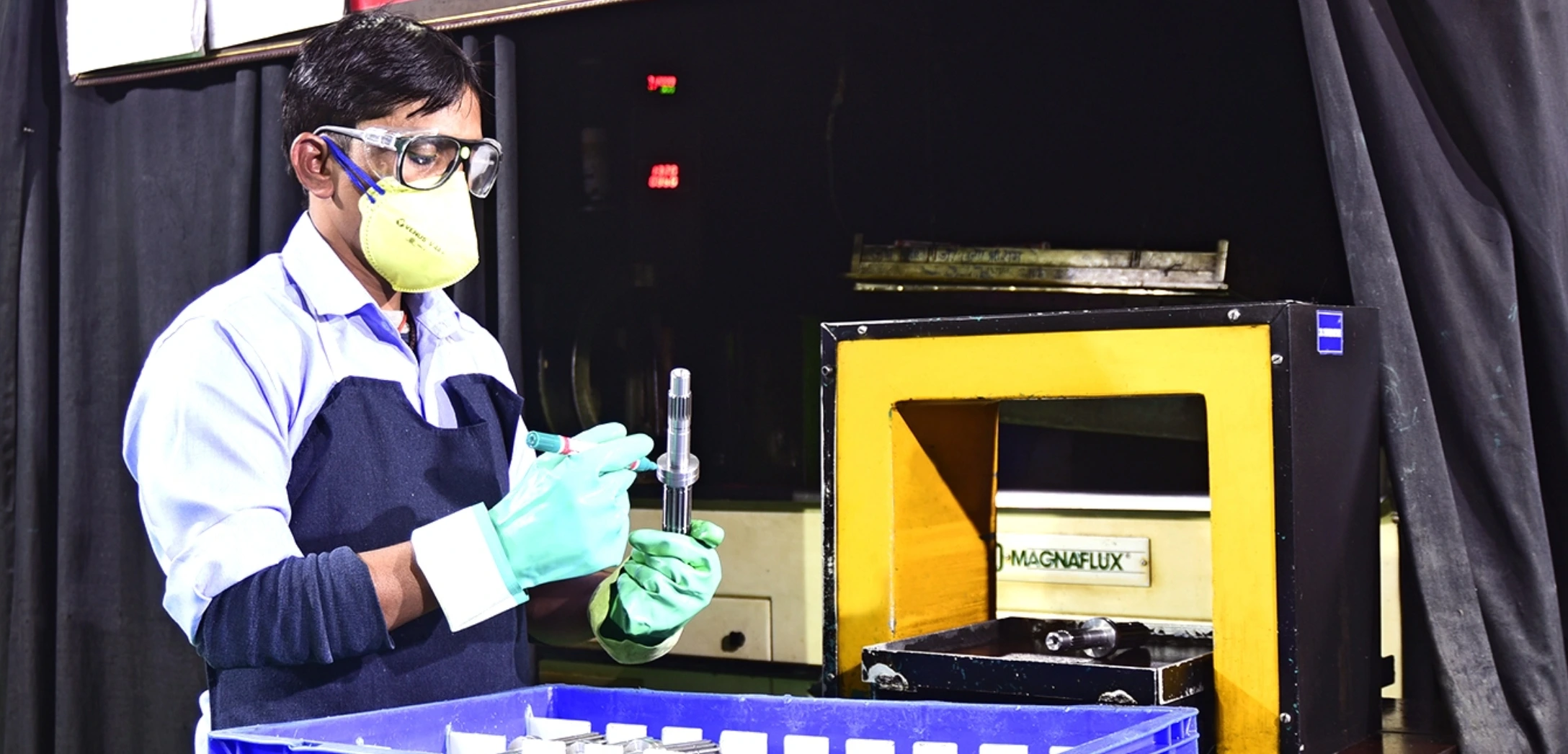

TESTING FACILITIES

Our in-house testing facilities are equipped with cutting-edge technology to ensure the highest level of precision and quality in every component we manufacture.

These advanced tools and machines enable us to thoroughly inspect and validate the mechanical, dimensional, and surface properties of our products, ensuring they meet stringent automotive industry standards.

Our testing capabilities include the following high-tech equipment

- Coordinate Measuring Machine (CMM) from Carl Zeiss

- Contour Testing Machine (CTM) from Carl Zeiss

- Roughness Testers

- Coating Thickness Testers

- Emission Spectrometer

- Profile Projectors

- Inverted Metallurgical Microscopes

- Air Gauges

- Universal Tensile Testing Machine (UTM)

- Spline Qualification Gauges

- Hardness Testers (BHN, HRC, HRB, HV)

CERTIFICATIONS

SFL holds prestigious certifications such as IATF 16949:2016, reflecting our commitment to high-quality standards and continuous improvement in the automotive industry. These certifications validate our stringent quality management systems and dedication to delivering reliable, precision-engineered components to our customers worldwide