Engineering

At SFL, our engineering capabilities are at the forefront of our commitment to delivering precision-designed automotive components.

Our comprehensive approach to engineering design and R&D allows us to deliver high-quality, innovative automotive components that align with our clients' evolving needs.

DESIGN

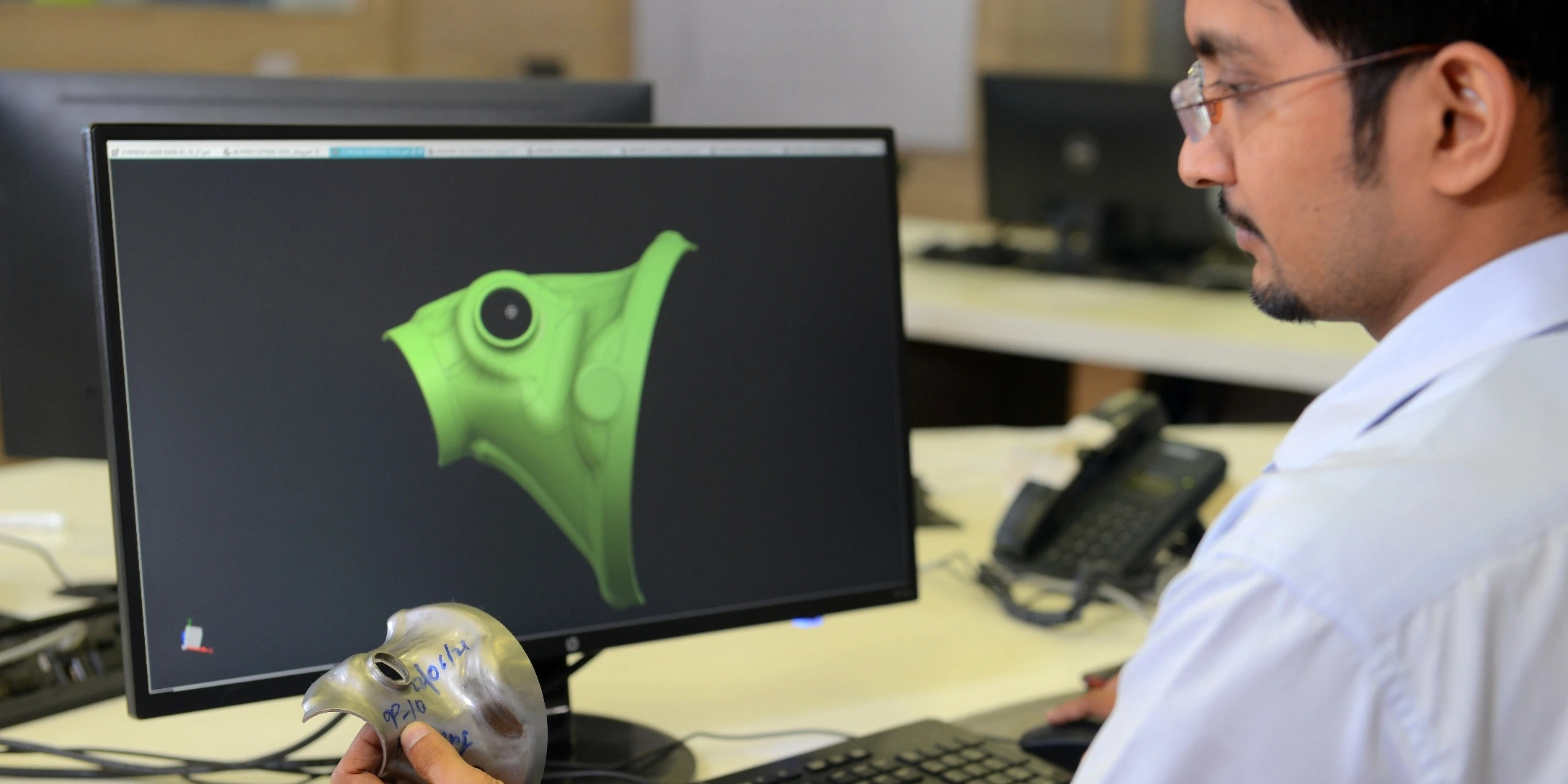

Our design process is supported by advanced software tools and methodologies, allowing our engineers to create precise and innovative designs tailored to customer specifications.

Utilizing CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) tools, we can visualize components in 3D, facilitating design optimization and ensuring that all specifications are met before production begins. This approach minimizes the risk of design flaws and streamlines the manufacturing process, enhancing overall efficiency.

RESEARCH AND DEVELOPMENT (R&D)

Our dedicated R&D team focuses on exploring new materials, manufacturing techniques, and industry trends. By staying at the cutting edge of technological advancements, we can develop products that not only meet current industry standards but also anticipate future demands.

TOOL ROOM

At SFL, the tool room is a critical component of our manufacturing capabilities, designed with the objective of supporting the production of high-precision automotive components.

Equipped with advanced CNC machining centers, EDM (Electrical Discharge Machining), surface grinding machines, wire cut and tool sharpening equipment, our tool room ensures the development and maintenance of high-quality tools and dies. These state-of-the-art machines allow us to produce intricate and precise tooling with consistent quality, which is essential for efficient production processes.