Blog

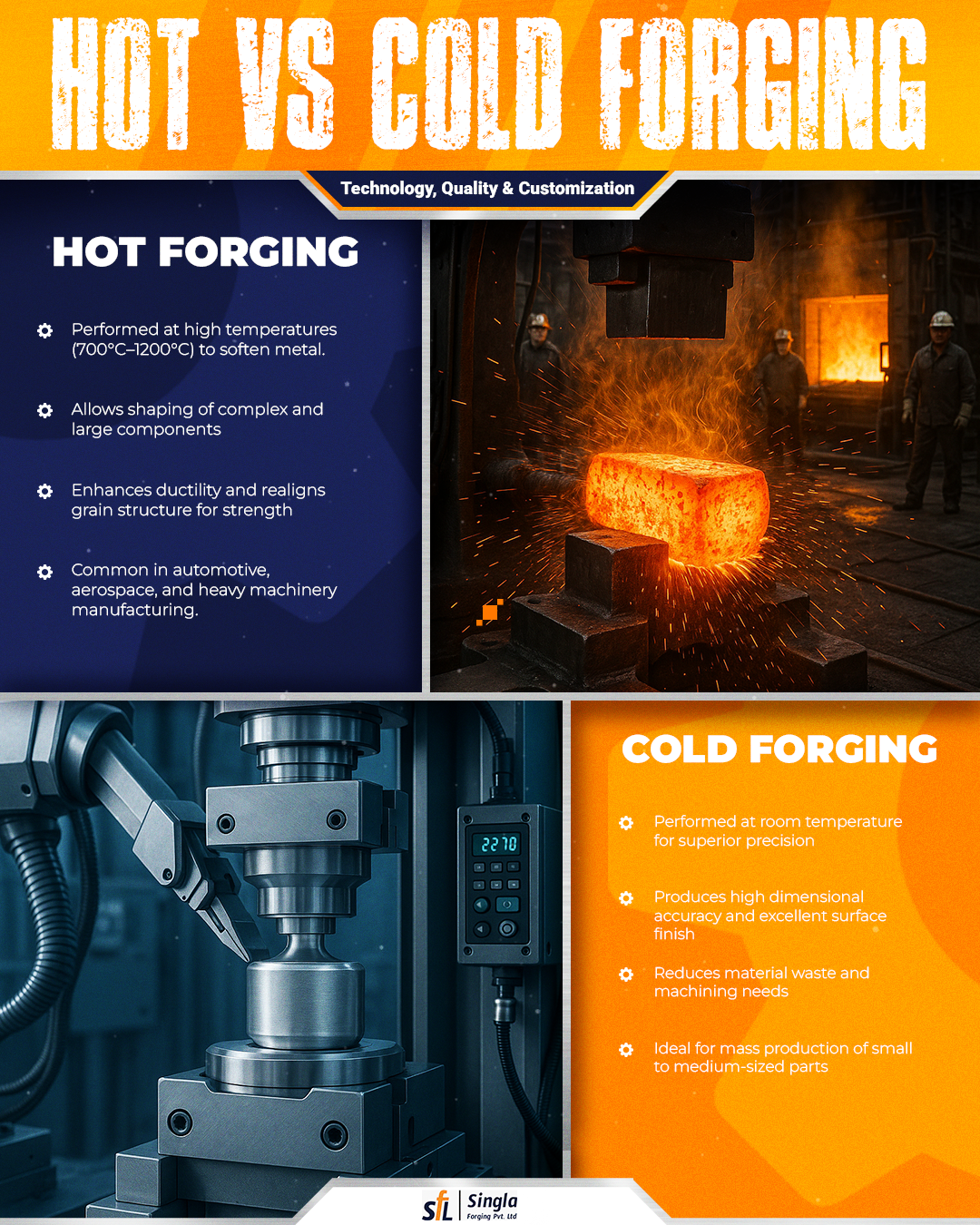

What Sets Our Hot and Cold Forged Components Apart: Technology, Quality & Customization

In the high-stakes world of precision forging, not all components are created equal. What truly distinguishes one supplier from another are the capabilities behind their processes, the rigor of their quality systems, and their agility in tailoring solutions to each client’s needs. At Singla Forging, these three pillars—technology, quality, and customization—are not just marketing words, but the foundations of how we engineer and deliver hot and cold forged components with distinction.

1. Technology: Pushing the Frontiers of Forging

Innovation in forging starts with the right machinery, processes, and R&D mindset. At Singla Forging, we leverage state-of-the-art hot, warm, and cold forging presses to cover a wide spectrum of component geometries and metallurgical requirements. The integration of precision CNC machining, advanced tooling, and modern software during product development helps us shrink tolerances, reduce waste, and speed up time to market.

What this means for you: even complex or challenging part designs can be reliably manufactured with consistent accuracy, repeatability, and structural integrity.

2. Quality: From Raw Material to Finished Part

Forging excellence is only as good as the weakest link in your supply chain. That’s why we maintain robust controls from material selection through final inspection. Our quality assurance systems encompass:

- Strict raw material checks and traceability

- In-process monitoring to prevent defects or deviations

- Comprehensive heat treatment, surface finishing, and testing to validate strength, hardness, and dimensional conformity

- Use of modern inspection tools and non-destructive evaluation to ensure every component meets the specification

Every forged piece that leaves our facility is backed by this multilayered assurance — no compromises.

3. Customization: Tailored Solutions, Scalable Execution

One size never fits all in advanced applications. Whether you’re in automotive, industrial machinery, or mobility sectors, your parts often demand unique geometries, material combinations, or performance features. That’s where our customization capabilities shine:

- Collaborative product development and prototyping to refine designs

- Flexible tool room capacity to create bespoke dies and tooling

- Modular production setups that adapt to you rather than force you into a fixed mold

- Capacity to scale from small pilot runs to full production volumes

With this focus, we transform client ideas into optimized forged solutions, rather than forcing clients to accept standard part designs.

Why This Matters for You

When you choose a partner like Singla Forging, you're not just buying a component — you're investing in reliable performance, consistency, and innovation. Our technological edge ensures precision. Our quality systems ensure durability. Our customization spirit ensures your product vision is respected and realized.

In industries where strength, weight, lifecycle, and dimensional fidelity matter, these three differentiators make all the difference — and they’re exactly what set Singla Forging apart.