Blog

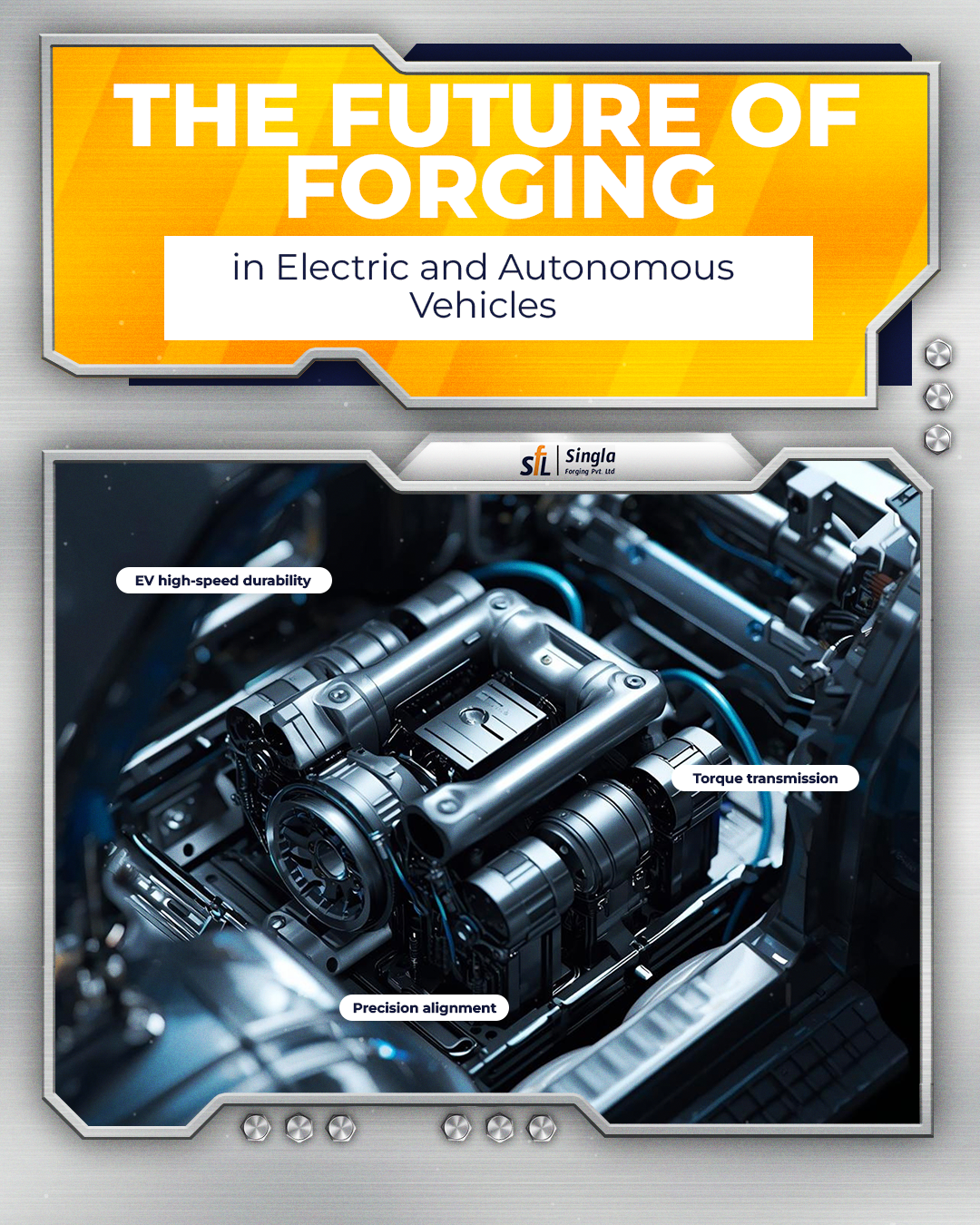

The Future of Forging in Electric and Autonomous Vehicles

The automotive industry is experiencing a major transformation. With the rise of Electric Vehicles (EVs) and Autonomous Vehicles (AVs), manufacturers are rethinking traditional design, performance, and production methods. At the heart of this revolution lies forging technology — a time-tested manufacturing process that is evolving to meet the demands of next-generation mobility.

Why Forging Still Matters in Modern Automotive Design

Forging has long been a cornerstone of automotive manufacturing due to the strength, durability, and precision it offers. Even as vehicles transition from internal combustion engines (ICE) to battery-driven and sensor-rich platforms, forged components continue to play a critical role. Their ability to withstand high loads, impact, and thermal stress makes them indispensable for applications such as bearings, shafts, housings, and structural components.

Electrification and Its Impact on Forging

Electric vehicles differ significantly from traditional cars in terms of power distribution, weight balance, and component layout. This shift creates fresh opportunities — and challenges — for forging:

- Greater Demand for High-Performance Lightweight Materials

EV manufacturers aim to extend driving range while managing battery weight. Forged aluminum, titanium, and high-strength steel parts offer excellent strength-to-weight ratios, helping automotive designers reduce vehicle mass without compromising safety. - Powertrain and Motor Components

Unlike ICE vehicles, EVs depend on electric motors and reduction gear systems. Many of these parts — rotors, hubs, gears, and couplings — benefit from forging because it increases metal density and fatigue resistance, which translates to longer life and better performance. - Thermal Management and Safety

Battery packs generate significant heat and require sturdy frames and thermal shields. Forgings offer the dimensional precision and structural reliability needed to create secure battery enclosures and rigid subframes.

Forging Meets Autonomy: Strengthening Future Mobility

Autonomous vehicles bring even more complexity. With increased reliance on software, sensors, and real-time decision systems, AVs must maintain unparalleled safety standards. In this environment, forged components help:

- Support Sensor and Control Unit Infrastructure

Lidar, radar, and camera modules must be mounted on structures that resist vibration and distortion. Forged housings and brackets provide enhanced rigidity and alignment precision, which are vital for sensor accuracy. - Improve Crashworthiness

Fail-safe structures are essential for autonomous navigation. Forgings — especially those made from high-strength steels — can be engineered to absorb impact energy efficiently, improving overall vehicle safety. - Longevity and Reliability

Autonomous ride-hailing and logistics services mean vehicles could run extended hours compared to personal cars. Forged components offer extended service life with minimal maintenance, making them ideal for commercial AV fleets.

Advanced Forging Techniques for the Future

The forging industry itself is innovating fast. Modern processes and technologies are reshaping how parts are made:

- Precision Hot Forging

Improves material flow and microstructure, resulting in components with consistent performance characteristics. - Industry 4.0 and Smart Manufacturing

AI-enabled quality checks and real-time forging analytics ensure higher yields and lower defect rates. - Hybrid Materials and Additive Integration

Forging is increasingly used alongside 3D-printed inserts or combined with advanced alloys to create multi-functional parts that meet the needs of tomorrow’s vehicles.

Environmental Advantages

Sustainability is integral to EV and AV design. Forging contributes positively by:

- Reducing Material Waste – Near-net-shape forging means fewer machining scraps.

- Lower Energy Use – Compared to casting or machining large batches, modern forging can reduce energy consumption.

- Recyclability – Common forging materials like steel and aluminum are highly recyclable and reusable.

Conclusion: Forging Is Driving the Future of Mobility

The automotive industry’s shift toward electrification and autonomy places new demands on materials and manufacturing. While vehicle architecture changes rapidly, one thing is certain — forging will remain a vital, adaptable, and forward-looking production technology.

Forging not only meets current performance needs but continues to evolve with advanced materials, precision manufacturing, and next-generation engineering. Companies that embrace these innovations are well positioned to shape the high-tech vehicles of tomorrow.