Blog

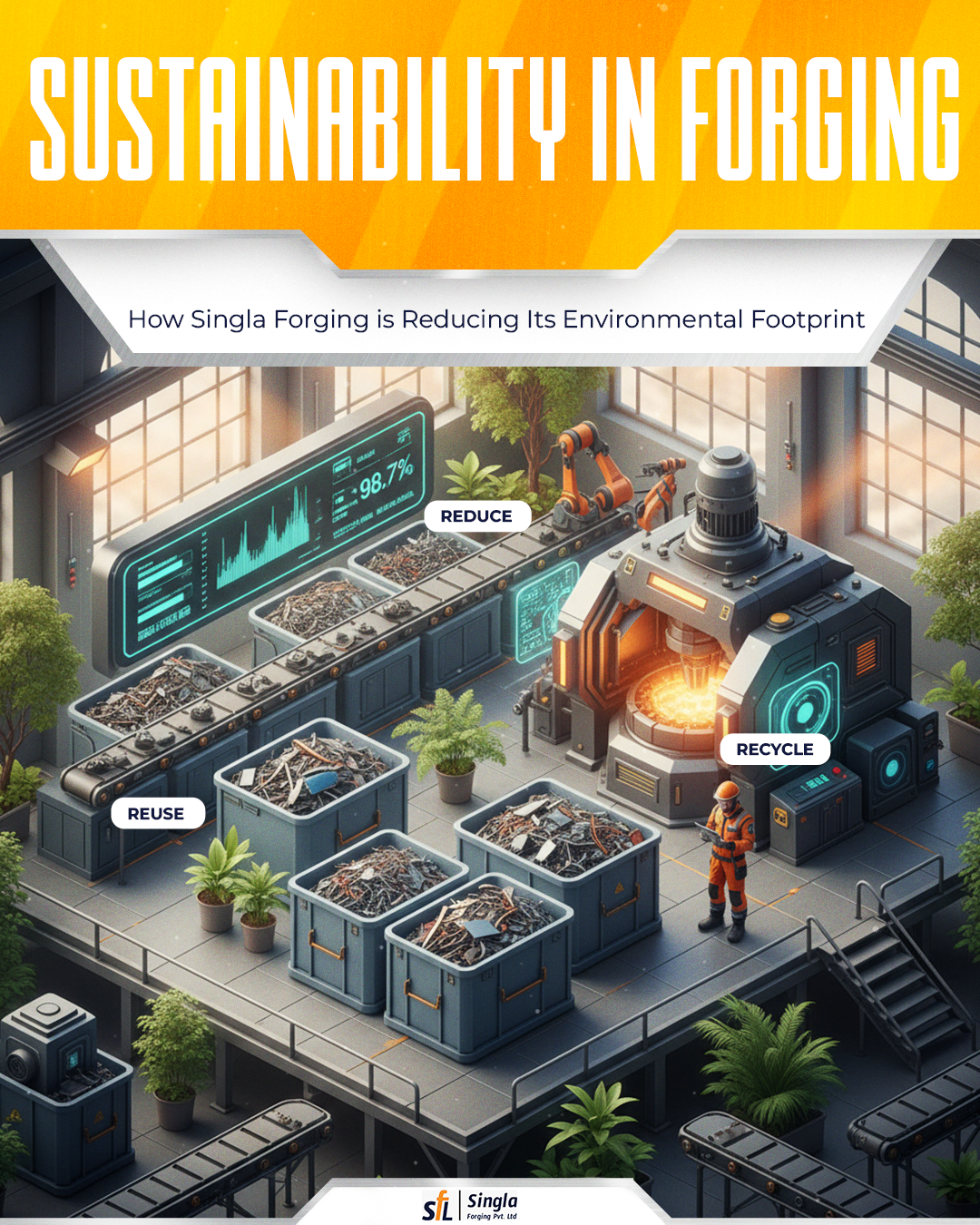

Sustainability in Forging: How Singla Forging Is Reducing Its Environmental Footprint

In today’s era of industrial advancement, sustainability has become more than a buzzword — it’s a responsibility. As industries evolve, manufacturing companies like Singla Forging Pvt. Ltd. are taking proactive steps to minimize their environmental impact while maintaining high production standards. Through innovative processes and a commitment to green manufacturing, Singla Forging is paving the way for a more sustainable future in the forging industry.

Understanding the Company and Its Role

With over three decades of experience, Singla Forging Pvt. Ltd. has established itself as a leader in hot, cold, warm, and aluminium forging. The company’s operations include precision machining, heat treatment, and surface finishing — all of which are traditionally energy-intensive processes. Recognizing this, Singla Forging has made sustainability a core part of its growth strategy.

Singla Forging’s Environmental Strategy

The company’s approach to sustainability revolves around improving efficiency, minimizing waste, and promoting eco-friendly manufacturing. Here are the key elements of their environmental initiatives:

- Energy-efficient machinery – The company invests in advanced equipment designed to reduce energy consumption while maintaining productivity.

- Material waste reduction – Precision engineering and optimized process design help minimize raw material waste across all forging operations.

- Optimized heat and surface treatment – Energy-saving technologies are used to ensure that heat treatment and finishing processes reduce emissions without compromising quality.

- Recycling and reuse – Scrap materials are systematically recycled, and the company promotes the use of recyclable and eco-friendly materials wherever possible.

- Efficient inventory management – Streamlined production and inventory systems help prevent overuse of raw materials and unnecessary wastage.

Why These Measures Matter in Forging

Forging is a resource-intensive industry, requiring large amounts of energy and raw material. Singla Forging’s sustainability practices directly address these challenges by:

- Lowering the carbon footprint through energy-efficient equipment.

- Preserving natural resources by minimizing waste and encouraging recycling.

- Reducing emissions from heat treatment and other high-energy processes.

- Ensuring that every stage of production contributes to a more responsible supply chain.

These efforts not only benefit the environment but also enhance the company’s competitiveness and long-term efficiency.

Beyond the Environment: The Broader ESG Approach

Sustainability at Singla Forging goes beyond environmental considerations — it encompasses social responsibility and good governance as well.

- Social Responsibility – The company regularly organizes employee health camps, training sessions, and skill-development programs. Employee wellbeing and workplace safety are given high priority.

- Governance – Transparency, ethical practices, and accountability form the foundation of the company’s governance framework.

- Community Involvement – Singla Forging contributes to community development through educational initiatives, vocational training, and environmental awareness programs.

This holistic ESG (Environmental, Social, and Governance) approach ensures that sustainability is integrated into every aspect of the organization.

The Value of Sustainability for Singla Forging

By embedding sustainability into its operations, Singla Forging is achieving multiple benefits:

- Cost efficiency – Reduced energy use and waste lead to lower operational costs.

- Market leadership – Customers and OEMs increasingly prefer suppliers with sustainable practices.

- Risk mitigation – Compliance with environmental regulations and responsible sourcing reduce long-term business risks.

- Reputation and trust – Commitment to sustainability strengthens relationships with employees, partners, and communities.

These advantages not only enhance brand reputation but also position Singla Forging as a forward-thinking leader in the global forging sector.

Challenges and the Road Ahead

While progress has been significant, sustainability in forging is an ongoing journey. Challenges include scaling up energy-efficient technologies across multiple plants, optimizing scrap utilization, and improving lifecycle impact measurement. Singla Forging continues to address these through continuous improvement, innovation, and long-term planning.

Final Thoughts

Singla Forging Pvt. Ltd. stands as a testament to how modern manufacturing can evolve responsibly. By focusing on energy efficiency, waste reduction, recycling, and social responsibility, the company is reducing its environmental footprint while maintaining its position as a trusted forging partner. As the global automotive and industrial sectors move toward greener supply chains, Singla Forging’s commitment to sustainability ensures it remains a vital and responsible player in the industry’s future.