Blog

Safety First: How Forged Parts Contribute to Crashworthiness in Passenger Vehicles

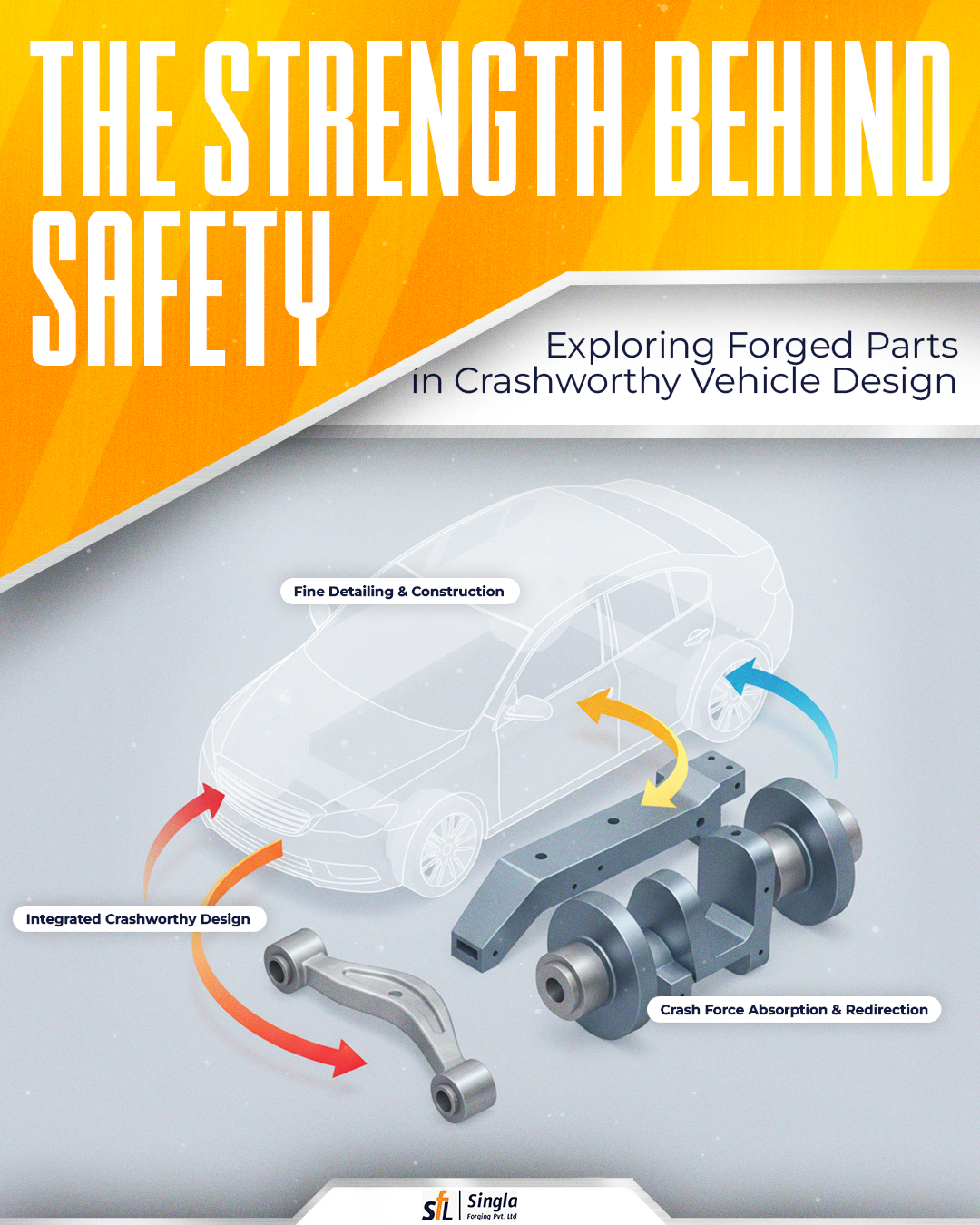

When it comes to passenger vehicle safety, crashworthiness is one of the most crucial design aspects automakers and suppliers must address. Crashworthiness refers to how well a vehicle protects its occupants in the event of a collision—how energy is absorbed, how the structure behaves, and how forces are managed and dissipated. Forged components play a vital role in enhancing crashworthiness. At Singla Forging, our expertise in forging—hot, cold, and warm—along with heat treatment, precision machining, and strict quality controls ensures that the parts we produce contribute significantly to vehicle safety. Here’s how.

What Is Crashworthiness & Why It Matters

Crashworthiness encompasses various factors:

- Energy absorption: During a crash, kinetic energy must be managed so that occupants are not exposed to sudden, high deceleration forces.

- Structural integrity: Key structural parts must retain shape under loads so that the passenger cell remains uncompromised.

- Deformation control: Crumple zones or sacrificial areas should deform in a controlled manner, absorbing impact rather than allowing disorganized failure.

- Fatigue resistance: Even before a crash, repeated stress, vibration, and load cycles should not degrade critical components to failure.

These combine to protect lives in real‐world crashes and also contribute to regulatory compliance, insurance ratings, and consumer trust.

Why Forged Parts Outperform in Crash Scenarios

Forging is a manufacturing process that shapes metal—by applying compressive forces—while refining grain structure, reducing defects like voids or inclusions, and improving mechanical properties. This gives forged parts several advantages relevant to crashworthiness:

- Higher Strength and Toughness

Forged components generally have superior tensile strength, yield strength, and impact toughness. The aligned grain flow resulting from forging allows the component to withstand higher loads without fracturing. This is particularly important for safety critical parts like steering knuckles, axle shafts, or load-bearing body frame members.

- Better Fatigue Performance

Because forging reduces internal defects and creates a more uniform microstructure, forged parts resist fatigue failure better than cast or welded parts. In crash conditions, this means components are less likely to initiate cracks or collapse prematurely.

- Controlled Deformation and Energy Absorption

Forged sections can be designed to deform in predictable patterns under load, thereby absorbing energy in a controlled manner. For example, forged monoblock parts with varying cross-sections can allow for thin and thick areas to transition smoothly, avoiding sharp joints or welds which may serve as failure points. This aids in designing components that behave reliably under crash loads.

- Reduced Risk from Joints, Welds, and Notches

Welds, joints, and sharp geometrical features are common initiation points for failure in crash events. Forged parts often reduce or eliminate the need for complex joining operations, minimizing weak spots. A single forged piece has no weld line vulnerabilities, less chance of stress concentration, and improved corrosion resistance across its structure.

- Optimised Material Use & Lightweighting

With stringent regulations and consumer demand for fuel efficiency, vehicle designers look to reduce weight while maintaining strength and safety. Forged steels and other alloys can achieve high strength at lower cross-sectional areas, helping to reduce weight without compromising crashworthiness.

Key Vehicle Components Where Forged Parts Make a Big Difference

Some of the vehicle parts most directly associated with crash safety that often rely on forging include:

- Steering components (knuckles, arms, tie rod ends)

These transfer loads during an impact and help maintain control or prevent separation.

- Axle shafts and wheel hubs

They bear torsional and bending stresses. Any failure here can lead to catastrophic outcomes.

- Body frame members, pillars, side-sills, and cross members

These parts form the passenger safety cell. Their ability to remain rigid around occupants while other parts deform is central to protecting people inside.

- Bumpers, crash beams, and energy absorbing structures

Though often viewed as sacrificial, these parts must behave consistently and predictably during impact. Forged or forged-reinforced components improve reliability.

How Singla Forging Ensures Safety Through Quality & Process

At Singla Forging, the commitment to crashworthiness doesn’t stop at selecting forging as the manufacturing method. Safety is integrated throughout process, material, and testing:

- Material selection & testing: Choosing high-grade steels or alloys with proven mechanical properties. Materials are tested for strength, toughness, and fatigue.

- Controlled forging and heat treatment: Ensuring proper temperature control, strain, and cooling rates so that the microstructure, grain flow, and hardness are optimized for both strength and ductility.

- Precision machining & minimal defects: After forging, components are precisely machined and inspected to adhere to tight tolerances, reducing stress concentrators.

- Joining and assembly considerations: When joints or assemblies are needed, minimizing weak features, ensuring proper joining techniques, and protecting corrosion-sensitive areas.

- Testing & validation: Both destructive and non-destructive testing methods, along with simulations where possible, are used to verify performance under load, including fatigue, impact, and energy absorption testing.

The Future: Innovations & Trends Enhancing Crashworthiness

Several evolving trends promise to further improve how forged parts enhance vehicle safety:

- Advanced high-strength steels (AHSS) and new alloys that allow lighter components without compromise.

- Simulation and virtual testing tools, such as finite element analysis (FEA), enabling more predictive crashworthiness design early in the development process.

- Topology optimization and design with purpose-built deformations (“triggers” or “crash beads”) so that components absorb energy in desired ways.

- Monobloc forging for body in white (BIW) parts, reducing joining and welding, improving uniformity, and eliminating weak joints.

Conclusion

Crashworthiness is not just a regulatory checklist—it’s a matter of lives. The manufacturing methods, materials, and design choices made today set the margin between survival and catastrophe in a collision. Forged parts, when produced to high quality standards like those at Singla Forging, are fundamentally better suited for safety-critical vehicle applications. They bring together strength, durability, predictable deformation, and structural integrity—all necessary ingredients in a safer vehicle.

By continually advancing our forging processes, materials know-how, and testing capabilities, Singla Forging is proud to help vehicle manufacturers build safer, more reliable passenger vehicles—because safety must always come first.