Blog

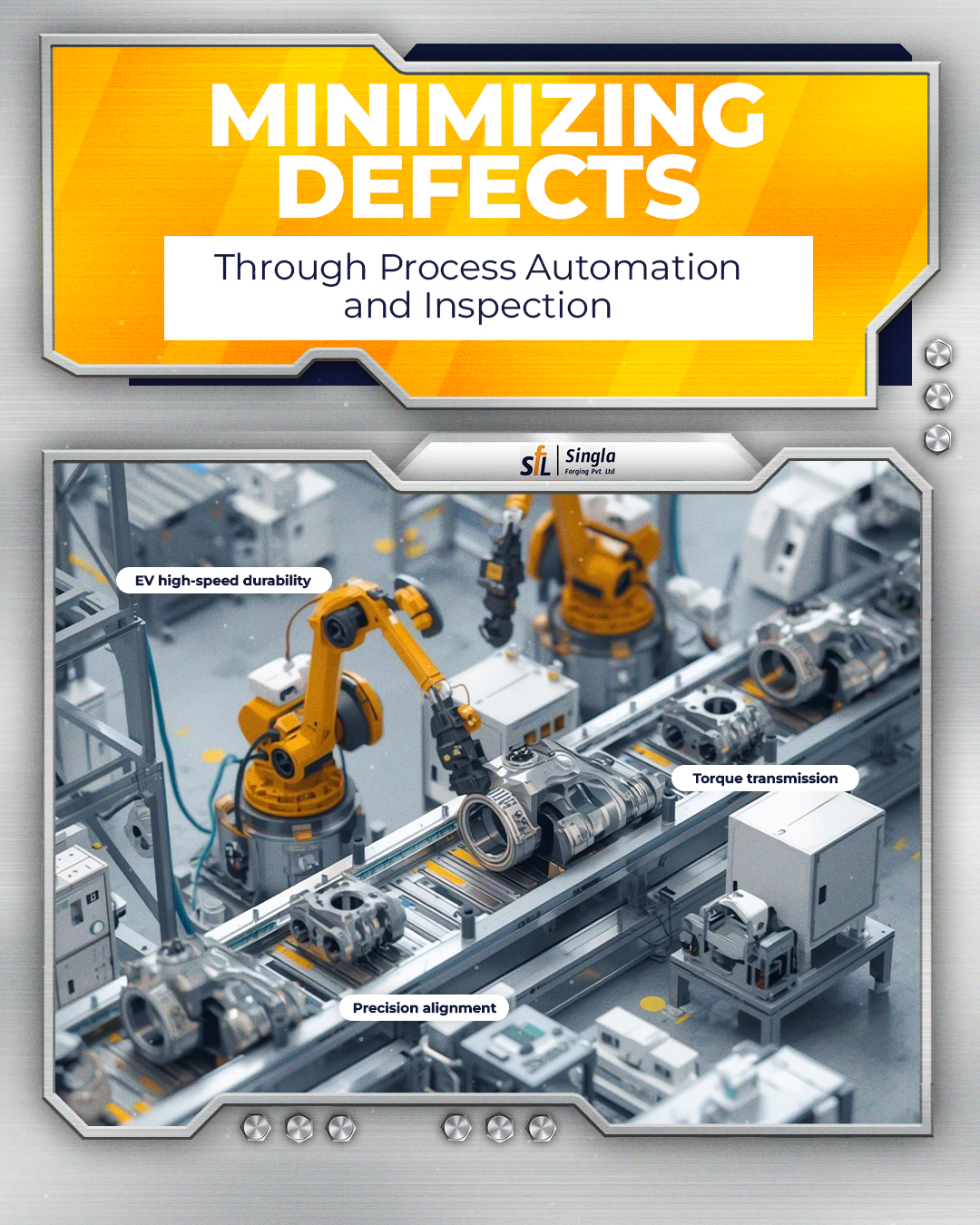

Minimizing Defects Through Process Automation and Inspection

In today’s fast-paced manufacturing landscape, quality is no longer just a competitive advantage — it’s a fundamental requirement. For industries like forging, where precision, strength, and reliability are non-negotiable, minimizing defects is a top priority. At Singla Forging, we understand that delivering products with zero defects isn’t just about correcting errors once they occur — it’s about preventing them through intelligent process design, automation, and careful inspection.

Why Defect Minimization Matters

Defects in forging products can have far-reaching consequences:

- Rising costs resulting from rejected parts and rework.

- Delays in delivery timelines

- Compromised product performance

- Erosion of customer trust and reputation

For manufacturers working with critical components used in automotive, aerospace, and heavy machinery, a single defect can lead to catastrophic failures. Therefore, minimizing defects is vital not only for operational efficiency but also for safety and compliance.

How Process Automation Reduces Defects

1. Standardizing Operations

Process automation ensures that every step is executed consistently. Manual operations, even by skilled workers, are subject to natural variances — differences in pressure, timing, or handling can introduce errors. Automated systems, however:

- Follow predefined parameters precisely

- Reduce human error

- Maintain consistent operations across shifts

This consistency is especially important in forging, where temperature, force, and timing must align to produce parts that meet strict tolerances.

2. Precision Control with Real-Time Monitoring

Modern automation integrates advanced sensors and control systems that monitor critical variables such as:

- Temperature

- Stroke force

- Die alignment

- Cycle duration

Real-time feedback allows immediate adjustments, preventing conditions that could lead to defects such as cracks, incomplete forging, or dimensional inaccuracies.

3. Enhanced Material Handling

Manual handling increases the risk of mix-ups, contamination, and damage to parts. Automation streamlines material flow through:

- Robotic part loading/unloading

- Conveyor systems

- Automated storage and retrieval

By minimizing unnecessary touchpoints, the chances of mishandling or surface blemishes are greatly reduced.

4. Intelligent Data Capture and Analytics

Automation doesn’t just control machines — it captures data. Advanced systems log performance metrics, process deviations, and product outcomes. Over time, this data can be:

- Analyzed for patterns leading to defects

- Used to refine process parameters

- Leveraged for predictive maintenance

This data-driven approach enables smarter decision-making and continuous process improvement.

The Role of Inspection in Defect Prevention

While automation significantly reduces the likelihood of defects, inspection provides the critical validation that products meet quality standards. Inspection should not be an afterthought — it must be integrated as part of the production process.

1. In-Process Inspection

Rather than waiting until the end of production, in-process inspection checks products during various stages. This allows:

- Early detection of deviations

- Immediate correction or process adjustment

- Prevention of large batches of defective products

Technologies such as laser scanning, thermal imaging, and inline measurement tools provide high-precision inspection without slowing down production.

2. Automated Vision Systems

Optical inspection systems use cameras and software to identify surface defects, improper shapes, and dimensional discrepancies. These systems excel at:

- Detecting micro-cracks and surface blemishes

- Comparing parts against digital blueprints

- Operating continuously without fatigue

By combining automation with machine vision, manufacturers gain consistent and objective inspection results.

3. Non-Destructive Testing (NDT)

Some defects are hidden beneath the surface. NDT techniques such as:

- Ultrasonic testing

- Magnetic particle inspection

- X-ray or CT scanning

ensure the internal integrity of forged parts without damaging them. Integrating NDT into the inspection stage prevents faulty components from ever reaching the customer.

Synergy Between Automation and Inspection

Process automation and inspection are strongest when they work together:

- Automated systems prevent many defects from happening in the first place.

- Inspection systems catch what automation may miss and ensure compliance with standards.

When inspection results are fed back into the automation control system, the process becomes self-correcting. This closed-loop approach leads to:

- Reduced defect rates

- Higher first-pass quality

- Greater customer satisfaction

Real-World Benefits at Singla Forging

By implementing advanced automation and integrated inspection strategies, Singla Forging:

- Produces components with high dimensional accuracy

- Reduces scrap and rework costs

- Delivers products with consistent quality

- Strengthens compliance with industry standards

- Enhances production efficiency and throughput

Our dedication to quality goes far beyond the manufacturing process. We invest in training, technology, and continuous improvement to ensure our forging solutions meet the exacting expectations of our customers across sectors.

Conclusion

Minimizing defects through process automation and inspection isn’t just a technological upgrade — it’s a strategic imperative. For forging manufacturers, it means improved quality, optimized costs, and stronger market credibility. At Singla Forging, we blend cutting-edge automation with rigorous inspection practices to deliver products that stand the test of performance and reliability.

Quality isn’t accidental — it’s engineered.