Blog

From Raw Material to Finished Part: Quality Control Processes at Singla Forging

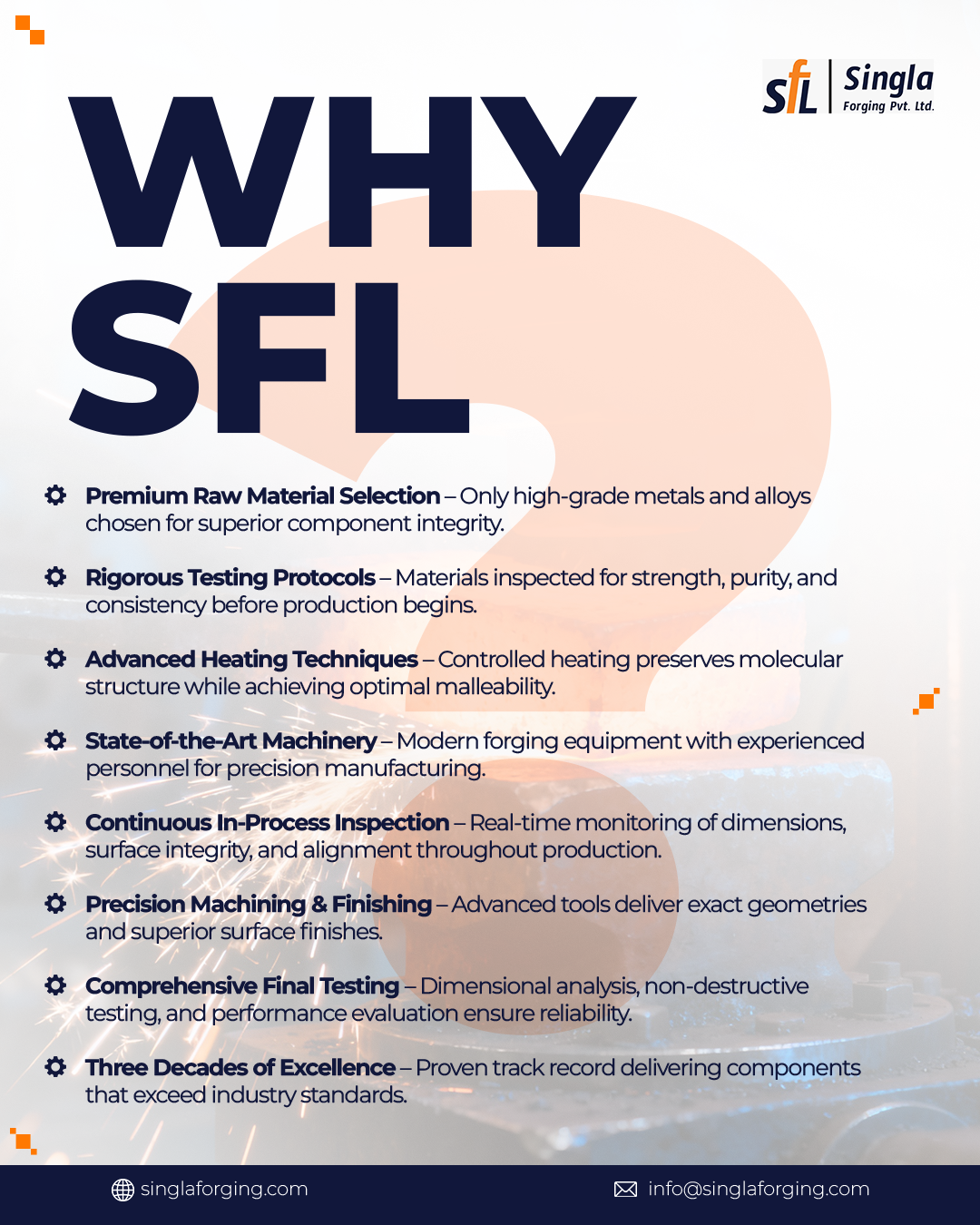

Singla Forging Pvt. Ltd. exemplifies the highest standards in forging excellence by implementing meticulous quality control processes at every stage, from raw material selection to the delivery of finished parts. This blog explores how Singla Forging ensures precision, reliability, and innovation throughout its production chain, drawing inspiration from its legacy, expertise, and adherence to global quality norms.

Commitment to Quality

Singla Forging’s reputation as a leading manufacturer stems from more than three decades of dedication to quality control. Strict quality guidelines are woven into their workflow, making sure every product meets demanding industry standards.

Raw Material Selection

The journey begins with the careful sourcing of raw materials. Only premium-grade metals and alloys are chosen for forging, as the integrity of the finished component heavily depends on the quality of the initial material. Expert engineers inspect and test incoming materials for essential properties like strength, purity, and consistency. This stringent assessment ensures that only materials meeting precise specifications move forward in the production process.

Cutting and Heating

Once materials pass the initial inspection, they undergo specific cutting and heating procedures. Singla Forging employs advanced heating techniques that prepare metals for shaping without compromising their molecular structure. Controlled heating is crucial for achieving optimal malleability and maintaining the mechanical properties required for end-use applications.

Forging Process and In-Process Inspection

Whether hot, cold, or warm forging, Singla’s production floors are equipped with state-of-the-art machinery and experienced personnel. Throughout these critical stages, continuous in-process inspections are conducted. Dimensions, surface integrity, and alignment are all regularly checked to ensure each part conforms to design specifications. This allows the team to detect any deviations early and take corrective action instantly.

Machining and Finishing

After forging, components are refined through machining and finishing processes. Singla Forging deploys precision tools and technologies to achieve desired geometries and surface finishes. Every item undergoes further checks for tolerances and quality, with only flawless parts proceeding to the next phase.

Final Inspection and Testing

No part leaves the plant without thorough final inspection. Advanced testing protocols include dimensional analysis, non-destructive testing, and performance evaluation under real-world conditions. Only those that excel in every criterion are approved for shipping to customers, ensuring reliability and longevity in the final application.

Innovation and Sustainability

Singla Forging’s commitment to continuous innovation supports its rigorous quality control measures. The company integrates the latest developments in aluminum forging and manufacturing technology, fostering an environment of improvement and sustainability. Responsible business practices and a diverse workforce further enhance the organization’s capacity for creativity, resilience, and quality assurance.

Singla Forging Pvt. Ltd. exemplifies how quality control—applied consistently from raw material selection to finished product—secures customer trust and industry leadership. Their holistic strategy, blending experience, expertise, and state-of-the-art technology, guarantees excellence in every forged component.